TEST METHODS

Our petrographers frequently examine a variety of materials. Petrography applies to samples of all types including, but not limited to:

-

Concrete

-

Mortar

-

Grout

-

Sealants + Membranes

-

Manufactures Stone

-

Shotcrete

-

Aggregates

-

Plaster

-

Stucco

-

Terrazo

STANDARDS

Standard Guide for Petrographic Examination of Aggregates for Concrete

This examination is used for the identification of rocks and minerals in new and existing concrete structures, ASTM C295 provides a guide detecting constituents that are deleterious to reinforced concrete. The analysis is used to identify:

• Chemically Unstable Minerals • Alkali-Silica & Alkali-Carbonate Reactive

• Volumetrically Unstable Materials Constituents

• Freeze Thaw Susceptible Aggregates • Aggregates that Negatively Impact • Aggregates Containing Iron Sulfide Water & Paste Demand

Durability Engineers can perform petrographic analysis to evaluate compliance of aggregates for local, state, or federal project specifications.

Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete

Hardened Air-Void Analysis is used to evaluate concrete's susceptibility to cyclical freezing and thawing, as well as, explain the reasoning as to why damage has occurred in hardened concrete. ASTM C457 is used to establish:

• Specific Surface • Spacing Factor

• Void Frequency • Paste-Air Ratio

Durability Engineers also reviews paste and aggregate contents, which contribute to strength and durability issues, thereby assisting clients in preventing/troubleshooting freezing and thawing related issues.

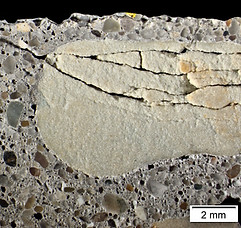

Standard Test Method for Petrographic Examination of Hardened Concrete

The standard practice for performing petrographic examination on hardened concrete, ASTM C856, is the industry standard for the evaluation of hardened concrete samples. This method is often used for identifying various issues, including but not limited to:

• Strength Issues • Delamination

• Dying & Plastic Shrinkage • Blistering

• Scaling • Mixture Compliance

Furthermore, ASTM C856 is the only application by which progressive mechanisms of distress can be formally discerned. Mechanisms such as:

• Freeze-Thaw • Corrosion

• Chemical Attack • Sulfate Attack

• Alkali-Silica Reaction & Alkali-Carbonate Reaction

Standard Test Method for Examination and Analysis of Hardened Masonry Mortar

This test method involves a combination of chemical and petrographic analysis per ASTM C856, thereby allowing our petrographers to identify the composition and proportions of the sample's constituents and ultimately the type of mortar (M, N, S and O) as described in ASTM C270, Specification for Mortar for Unit Masonry. ASTM C1324 is also used for understanding the composition of mortar in historical structures where restoration and preservation is of concern.

Standard Test Method for Petrographic Examination of Dimension Stone

For dimension stone, ASTM C1721 provides a guide for petrographic techniques and properties used in the identification of minerals and constituents which have adverse effects to the performance of the subject material in its proposed environment. The identification of minerals and corresponding properties within the sample through petrographic examination paired with XRD & SEM help to discern the following:

• Chemically Unstable Minerals • Volumetrically Unstable Materials

• Freeze-Thaw Susceptibility • Materials Susceptible to Deicers

• Staining & Surface Color Change • Aesthetic Changes due to Weathering

Standard Test Method for Examination and Analysis of Hardened Concrete Using Scanning Electron Microscopy

Photographing and identification of submicroscopic features and/or failure mechanisms, ASTM C1723, provides a guide via scanning electron microscopy (SEM) with energy dispersive x-ray spectroscopy (EDX). Durability Engineer's Materials scientists employ ASTM C1723 in order to identify:

• Unknown Materials/Deposits

• Corrosion Products

• Surface Contamination and Staining